Heat wave

For companies that are running short on warehouse or DC space, mezzanines can be an attractive solution. For one thing, installing a mezzanine can eliminate the need to relocate. For another, it can avoid the expense and hassle of building an addition.

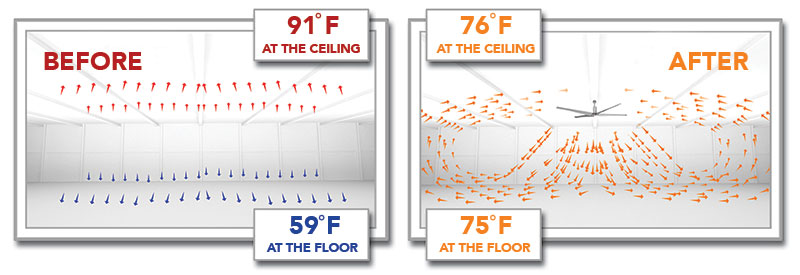

But mezzanines also have a downside: Heat rises, and because the mezzanine is up high, close to heat-emitting light fixtures, the temperature could run as much as 20 or even 30 degrees higher than temps on the floor. That makes things uncomfortable for workers and could result in heat stress. It also raises the risk of product spoilage or packaging failure due to moisture from condensation.

Too-high temperatures can also keep an operation from running at peak efficiency. When people are fatigued from the heat, order accuracy can suffer, warns Brian Neuwirth, vice president of sales and marketing at warehouse equipment company Unex Manufacturing Inc. in Lakewood, N.J.

FINDING YOUR COMFORT LEVEL

When DCs go to tackle the worker comfort problem, the first impulse is often to put in fans, but fans alone might not be the best solution. (In fact, they probably aren't.) "If it's 20 degrees hotter at the ceiling and you just put in a fan, then it's going to be roughly 10 degrees hotter than at the floor," says Christian Taber, senior applications engineer at the fan company Big Ass Solutions. "That is not necessarily the best scenario."

That's because temperature isn't the only factor that contributes to workers' perception of how hot they are, or to their safety, says Taber. He points to standards from the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE), which identify six factors that help determine how comfortable a person feels: air temperature; radiant heat (heat emitted by warm objects such as lighting fixtures, machinery, and people); air speed; humidity; clothing insulation level; and metabolic heat, which increases with activity.

"All six of those together really drive whether or not a person's comfortable, or whether or not they're going to have heat stress," says Taber. "For example, if you have to wear two full layers of clothing for safety reasons and you're doing high-activity-level work, then the temperature at which you're going to go into heat stress is going to be dramatically lower than if you're wearing shorts and a T-shirt and you're engaged in light activity and there's a nice breeze blowing. So, temperature alone doesn't really define it. It's a combination."

Studies show that productivity starts to drop when the perceived temperature rises above 77 degrees Fahrenheit, says Taber. Heat stress—heat-induced physical problems that can include cramps, heat exhaustion, and heat stroke—can become a problem when temperatures reach the mid-80s.

FIND THE ROOT CAUSE

Although DCs often look first to fans, a better approach to remediating heat issues is to step back and try to determine the root cause of the problem, Taber says. His company usually looks first at the ventilation or exhaust system when evaluating a client's facility, he reports. "If the building does not have sufficient exhaust that takes the hottest air off the ceiling, the other solutions really don't work as well," he explains. "If you're not bringing fresh air in low (and) you're not exhausting hot air up high, then that heat tends to build up (near the ceiling)."

Other possible root causes include poor roof insulation and lighting that emits too much heat—or even the number of workers in a space or the clothing they're wearing. Focus on the changes that will give you the biggest return, advises Neuwirth.

Neuwirth recommends starting by asking yourself what's putting off the most heat. Often, the answer is an internal heat source, such as lighting or motors from conveyors or other equipment. Solutions could include replacing motor-driven conveyors with nonmotored gravity units or replacing old-fashioned metal halide lights with light-emitting diode (LED) or fluorescent lights, which give off less heat.

Sometimes, it's necessary to isolate the source of heat from the rest of the building. Taber cites a project where a large oven was throwing off a huge amount of heat. "Rather than exhausting air out of the whole building, we isolated the oven and put it essentially in a closed space, and then exhausted that heat directly out of the building," he recalls. "That kept that heat from being spread throughout the building and overheating everyone."

BRING IN THE FANS

Once you've dealt with the major problems, the next step is to circulate the air to equalize the temperature from floor to ceiling. This is where fans come in.

But the answer might not be traditional ceiling-mounted fans. Those might not work over a mezzanine, because safety regulations may require a minimum distance between the mezzanine floor and an overhead fan.

That might mean companies have to get creative with their fan placement. "Generally speaking, when we're dealing in mezzanines, we're looking at either mounting directional fans off a mezzanine blowing in, or mounting them around the interior of the mezzanine," says Taber. A fan mounted to the side can pull the hottest air from the ceiling level and push it down toward the floor, creating a more uniform temperature from floor to ceiling.

|

|

| Fans mounted on poles, beams, or walls can be used in cases where a ceiling fan would be too close to workers' heads. (Photos courtesy of Rite-Hite Inc.) | |

High-volume, low-speed (or HLVS) fans are usually used to mix hot and cold air, according to Dan Anderson, product manager for Milwaukee, Wis.-based Rite-Hite Inc. Once the air is circulating, additional fans can be used to boost air speed so occupants feel cooler. A high-volume, high-speed (HVHS) fan is usually used for that purpose.

As for fan positioning, some companies place fans on tall posts on the lower floor, which is more stable than a mezzanine, and adjust them so that they blow across the platform. An alternate approach is to place fans at one side of the mezzanine to blow air across and another series of fans on the opposite side to pull air over the platform, says Bradley A. Lehman, regional sales manager for Wildeck Inc. in Waukesha, Wis.

An automated fan-control system is optimal. For one thing, says Taber, automated controls free up the workers to focus on the task at hand. "For another, you know it's going to do the right thing, rather than have user interaction muddle things up," he says. "We've seen fans spinning in the wrong direction, or off when they should be running to help increase comfort. By using an automated controller to take that over ... (you can help ensure) the fans are going to run appropriately whatever the conditions."

WINTER WOES

Even in colder weather, heat can be a problem. "A traditional heating system might have a discharge air temperature that's 100, maybe 125, degrees Fahrenheit," Taber says. That air will rise toward the ceiling, with the result that, in a DC where the floor-level temperature is 65 degrees, the temperature could be as high as 75 or 85 degrees at the ceiling. "When you're dressed for the winter and it's 85 degrees at the ceiling, that can be problematic," he notes.

Summer or winter, hot air rises to the ceiling and stays there, while colder air remains at floor level. Adding a fan near the ceiling mixes and circulates air to create a more uniform temperature. (Photo courtesy of Rite-Hite Inc.)

During colder months, dampness from condensation can create problems too, says Anderson. That's because doors and windows are usually kept closed, so there's less ventilation. The resultant moisture can wreak havoc with products—particularly when products are stored on top of mezzanines, where it's likely to be warmer, even if the air is circulating. "Condensation and cardboard or produce or other items can cause different problems, whether it's breakdown in cardboard or ruining raw materials or spoiling produce," he notes. Gentle air movement from an HVLS fan can help in that situation.

A HOLISTIC APPROACH

There's no single solution to tackling a heat problem effectively, Anderson says. "It's not a one size fits all. You don't want to buy these things out of a catalog, because they all need to interact with each other." He suggests bringing in consultants and having them work with an end user from the client company who understands the work processes. The knowledge a DC employee brings to the table can really make a difference in coming up with the best solution for a particular operation.

"The one thing that I always try to stress is, these applications, they're more of an art than a science," says Anderson. "You have to look at the space as a whole and really find out what's happening and where it's critical to get the air moving. ... There's not one solution."

Related Articles

Copyright ©2024. All Rights ReservedDesign, CMS, Hosting & Web Development :: ePublishing