Spotlight on ... automation

Decking system: Cargo handling and restraint system specialist Ancra Cargo has introduced AutoDeck, an automated integrated decking system (in photo above). The AutoDeck system lets loading dock staff and drivers set the height of each beam with the push of a button to easily create customized decking solutions. Prior to the introduction of manual decking systems decades ago, the space available in trailers was either not fully utilized or pallets were stacked on top of each other, potentially damaging cargo. According to the manufacturer, the new decking system allows for better shipping efficiency, reduces losses resulting from cargo damage, and increases load averages by 10 to 30 percent. (Ancra Cargo)

Modular sortation system: Robotics and warehouse automation manufacturer GreyOrange has debuted its latest modular sortation system. Designed for distribution and logistics centers serving retail, courier, and express companies, the Flexo robotics system offers versatility, portability, and sortation efficiency thanks to fluid layouts that require minimal additional infrastructure, the company says. The system can operate 24 hours a day, 7 days a week, reducing the cost per shipment and dependence on additional labor during peak times. The artificial intelligence-enabled robotics system can be adapted to meet evolving business needs—for example, by scaling up to handle peak-period volumes and scaling down during nonpeak times to minimize operating costs. According to the manufacturer, Flexo is designed to allow for fast implementation—in as little as 15 days—due to its simple design, modularity, and standardization. (GreyOrange)

Modular sortation system: Robotics and warehouse automation manufacturer GreyOrange has debuted its latest modular sortation system. Designed for distribution and logistics centers serving retail, courier, and express companies, the Flexo robotics system offers versatility, portability, and sortation efficiency thanks to fluid layouts that require minimal additional infrastructure, the company says. The system can operate 24 hours a day, 7 days a week, reducing the cost per shipment and dependence on additional labor during peak times. The artificial intelligence-enabled robotics system can be adapted to meet evolving business needs—for example, by scaling up to handle peak-period volumes and scaling down during nonpeak times to minimize operating costs. According to the manufacturer, Flexo is designed to allow for fast implementation—in as little as 15 days—due to its simple design, modularity, and standardization. (GreyOrange)

Automated sortation: Solution Net Systems (SNS) has expanded its automated sortation portfolio with the addition of the SNS Modular Sortation System. The new system is ideal for companies looking to improve their order and inventory accuracy as well as reverse logistics, order fulfillment, receiving, and picking and packing operations.

Automated sortation: Solution Net Systems (SNS) has expanded its automated sortation portfolio with the addition of the SNS Modular Sortation System. The new system is ideal for companies looking to improve their order and inventory accuracy as well as reverse logistics, order fulfillment, receiving, and picking and packing operations.

The SNS Modular Sortation System is built for a wide range of materials, including polybags, padded envelopes, and small and large cartons. This quiet, scalable solution can handle multiple divert points on a single belt and utilizes 24 motor-driven rollers to provide energy efficiency. SNS says the all-electric design saves money by eliminating the reliance on inefficient pneumatic solutions and the associated costs of installing, operating, and maintaining compressors.

Other benefits of the system include a safe divert mechanism that protects personnel by reducing their exposure to large mechanical pushers. Using the company's "FAST" software, the portable and modular sortation solution can integrate into an existing system and expand to meet an operation's growing needs, the manufacturer says. (Solution Net Systems Inc.)

Robotic package unloader: Honeywell has introduced an automated robotic solution for unloading packages from truck trailers and shipping containers at distribution centers. The robotic unloader drives into a trailer or container and uses machine vision to identify various package shapes and sizes as well as the optimal approach to unloading. A robotic arm with a series of small suction cups conforms to the package shape to gently extract it from the stack. A conveyor below the arm can serve as a sweeper for packages to move them out of the trailer.

Robotic package unloader: Honeywell has introduced an automated robotic solution for unloading packages from truck trailers and shipping containers at distribution centers. The robotic unloader drives into a trailer or container and uses machine vision to identify various package shapes and sizes as well as the optimal approach to unloading. A robotic arm with a series of small suction cups conforms to the package shape to gently extract it from the stack. A conveyor below the arm can serve as a sweeper for packages to move them out of the trailer.

The robotic unloader uses artificial intelligence to operate fully autonomously inside of a trailer, which significantly reduces the manual effort required to operate receiving docks for retail merchandise and parcel distribution centers, the company says. This smart robotics offering works with existing fleets and is designed to help customers improve workplace safety, reduce staffing challenges, and minimize damage to packages. (Honeywell)

Automatic bagger: Pac Machinery, a manufacturer of equipment and materials that are used in the flexible packaging industry, has unveiled the latest version of its Rollbag R1275 automatic bagger. Designed to increase production rates and simplify user interaction, the Rollbag R1275 features compact, low-profile seal-flattening fingers and a new, optional bag opener that stretches the bag to a specific opening size and shape to facilitate filling. A new bag profiler option helps maintain the bag's shape by keeping it flatter as the bag fills, thus preventing bulk materials from distorting the bag.

Automatic bagger: Pac Machinery, a manufacturer of equipment and materials that are used in the flexible packaging industry, has unveiled the latest version of its Rollbag R1275 automatic bagger. Designed to increase production rates and simplify user interaction, the Rollbag R1275 features compact, low-profile seal-flattening fingers and a new, optional bag opener that stretches the bag to a specific opening size and shape to facilitate filling. A new bag profiler option helps maintain the bag's shape by keeping it flatter as the bag fills, thus preventing bulk materials from distorting the bag.

The most significant improvement, however, is the new infeed funnel mounting system. The funnel mount is designed to accommodate a wide variety of automatic feeding devices, making funnel changes easier and faster to accomplish. For extra versatility, this automatic bagger can be used with scales, counters (including an advanced vision-counting system for small products), and other feeding devices. In addition, the automatic bagger is engineered to connect with robotic systems.

An optional thermal printer enables the printing of graphics, bar codes, date codes, and text. (Pac Machinery)

Picking robot: With e-commerce and distribution businesses facing staffing shortages, Kindred Inc., a manufacturer of piece-picking robots, has unveiled Sort, a picking robot with human-like grasping capabilities that separates multi-SKU batches into individual customer orders. According to the company, Sort picking robots utilize AutoGrasp, a robotics intelligence platform that becomes smarter, faster, and more accurate over time. This platform combines vision, grasping, and manipulation algorithms to deliver fast, accurate picking. Sort was designed to easily integrate with any warehouse management software and can evaluate items in real time, picking and matching them to individual customer orders. (Kindred Inc.)

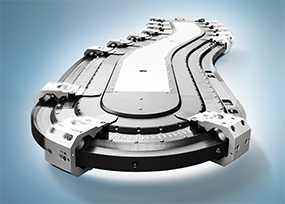

Drive technology: The eXtended Transport System (XTS) from Beckhoff Automation is now available in the United States. According to the manufacturer, the EtherCAT-enabled XTS offers paradigm-shifting capabilities for motion control and mechatronics by combining rotary- and linear-drive principles into a new modular platform. With its compact and flexible design, the advanced mechatronic system can reduce machine footprint by up to 50 percent, the company says.

Drive technology: The eXtended Transport System (XTS) from Beckhoff Automation is now available in the United States. According to the manufacturer, the EtherCAT-enabled XTS offers paradigm-shifting capabilities for motion control and mechatronics by combining rotary- and linear-drive principles into a new modular platform. With its compact and flexible design, the advanced mechatronic system can reduce machine footprint by up to 50 percent, the company says.

XTS was engineered to support efficient integration for motion-control applications in many industries. With attached mechanical guide rails, XTS motor modules feature directly integrated power electronics, EtherCAT communication, and position measurement. An unlimited number of wireless XTS movers can be controlled with high dynamics at up to four meters per second on customizable paths. (Beckhoff Automation)

Related Articles

Copyright ©2024. All Rights ReservedDesign, CMS, Hosting & Web Development :: ePublishing