Ryder opens Silicon Valley technology lab to prepare for waves of AI in supply chain

Office will be led by co-founders of Baton, the transportation tech startup acquired by Ryder last year

Transportation and logistics provider Ryder System Inc. says it is preparing for a coming wave of artificial intelligence (AI) solutions in supply chain networks with the launch this week of a Silicon Valley-based technology lab led by the founders of tech startup Baton, which it acquired last year.

Miami-based Ryder acquired Baton in 2022 for an undisclosed sum, noting that the then-three-year-old firm’s software could speed up urban truck routes by creating local “drop zones.” Baton’s new mission is to pioneer a suite of customer-facing technologies designed to let Ryder’s customers digitize and optimize their transportation and supply chain networks at a level not currently available in the industry, Ryder said.

Leading Ryder’s innovation lab are Andrew Berberick and Nate Robert, who together co-founded San Francisco-based Baton and are now Ryder’s co-chief product and technology officers.

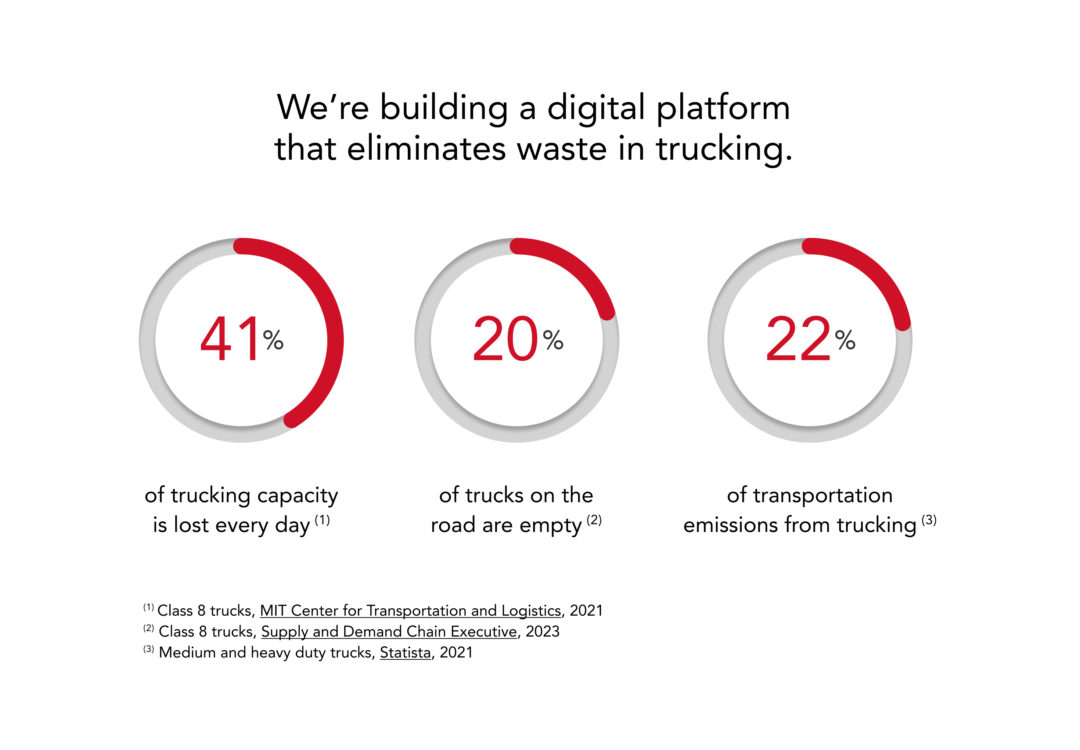

Baton’s original technology was a transportation management system called Radius that optimized the schedules of local drivers, finding freight on local load boards to complement gaps in drivers’ schedules. The firm then shifted its focus to the software that it now plans to apply more broadly to Ryder’s 50,000 customers, breaking down corporate data silos to match the waste and surplus of truckers’ empty backhaul miles, Berberick says.

Some innovation labs in the logistics sector get a bad reputation for developing ideas that never go anywhere, since they were incubated far away from real world customers, says Berberick. However, the Baton lab intends to buck that trend by traveling far outside California’s famous tech hub—he spent last week huddled with Ryder transportation customers in the busy trucking corridor of York, Pennsylvania—and applying lessons about industrial trailers, freight, and drivers.

As it pursues that goal, Baton will be able to lean on the deep pockets of its new owner. According to Ryder, “The establishment of a Silicon Valley-based technology lab is a natural evolution for Ryder, as we build on the $1.3 billion in strategic investments we’ve made over the past five years to develop, acquire, and invest in innovative technologies, products, and services that help make our customers’ logistics networks more efficient and resilient,” Karen Jones, Ryder’s CMO and head of new product development, said in a release. “To build on that success, it’s paramount we continue to invest in recruiting the brightest technology minds out there and provide them with a startup environment where they have the space and freedom to create, along with the resources of a $12 billion company.”

Related Articles

Copyright ©2024. All Rights ReservedDesign, CMS, Hosting & Web Development :: ePublishing