Honeywell opens "robotics innovation hub" in Pittsburgh

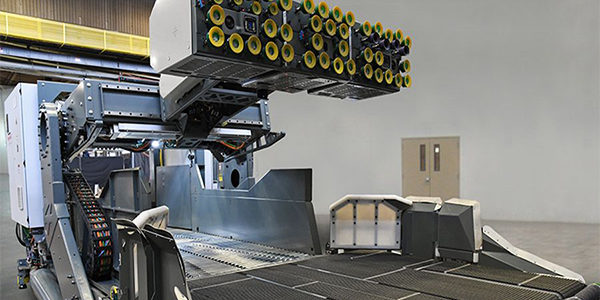

Industrial equipment and technology provider Honeywell International Inc. on Thursday unveiled a "robotics innovation hub" in Pittsburgh, saying the unit would develop artificial intelligence, machine learning, computer vision, and advanced robotics for use across supply chains.

The move is Honeywell's latest move to expand its presence in providing supply chain automation products for e-commerce and home delivery since the Charlotte, North Carolina-based company paid $1.5 billion in 2016 to acquire the material handling automation provider Intelligrated Systems Inc. Honeywell also owns the mobile computing and auto-ID provider Intermec Inc. and the voice-directed picking system vendor Vocollect.

The new Honeywell Robotics division will be charged with helping to shape the warehouse and distribution center of the future, answering customers' demands for automated solutions, software, and robotics to deliver increased speed, accuracy, and throughput in complex material handling environments, the company said.

Honeywell has tapped industry veteran Joseph Lui to lead the unit, pointing to his experience working as director of Industrial IoT and Automation Technologies, Robotics, for Amazon.com Inc.

Lui will help to pull together a number of Honeywell's initiatives and investments in warehouse automation, including the company's Momentum warehouse execution system (WES) software platform and its partnership with artificial intelligence (AI) researchers at Pittsburgh-based Carnegie Mellon University's National Robotics Engineering Center. Honeywell has also used its Honeywell Ventures investment fund to back the warehouse robotics startups Soft Robotics and Attabotics.

Honeywell Robotics will act as a hub to pull together those various Honeywell assets around the world and create products and solutions to solve supply chain logistics problems, said Lui, who has the title of vice president and general manager of robotics, computer vision, and AI.

The unit plans to make an unspecified number of hires for engineering roles such as software engineers and robotics designers in the near future, Lui said in an email. That team "will grow our robotic solutions portfolio both organically and inorganically," continuing to develop the company's home-grown Honeywell Universal Robotic Control (HURC)-based robotic solutions as well as collaborating with startups and academics, he said.

More specifically, they will develop AI, machine learning, and computer vision technologies to automate specific supply chain process steps, such as unloading, receiving, decanting, stowing, picking, packing, sorting, shipping, moving, and loading, he said. Those systems are commonly used for tasks such as object detection, identification, and tracking, robotic motion planning, navigation, and mission planning, storage space allocation, and inventory buffering, he said. "We are building these core robotic capabilities to enable our robotic solutions to perform at their highest possible levels at all times and quickly adopt to their operating environments," Lui said in the email.

"As AI, machine learning and computer vision become commonplace, Honeywell Robotics will create innovative, breakthrough technologies to help customers alleviate skilled labor shortages, reduce safety risks and eliminate inefficient tasks," Lui said in a release. "The use of technology - including advanced warehouse execution systems, 3D storage and sortation solutions to improve capacity and efficiency, and autonomous mobile robots - is just the start of the digital transformation in warehouses."

Pittsburgh, are you ready for the next generation of warehouse #robotics? See more: https://t.co/fWfpO37wIM pic.twitter.com/Y562lfDu4J

— Honeywell (@honeywell) October 25, 2019

Related Articles

Copyright ©2024. All Rights ReservedDesign, CMS, Hosting & Web Development :: ePublishing