Upload your press release

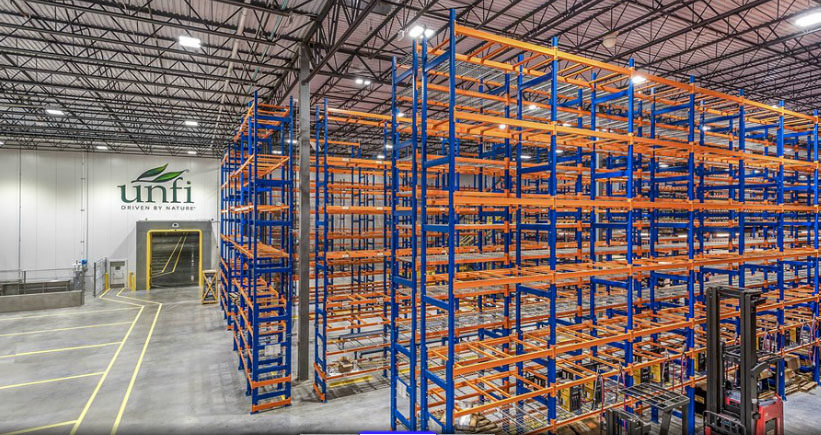

HANNIBAL INDUSTRIES¹ TUBERACK SELECTED FOR UNITED NATURAL FOODS, INC. EXPANSION

March 17, 2016 - (Los Angeles, Calif.) - Today, Hannibal Industries, Inc. announced that it has been selected by leading system integrator, Storage Solutions of Westfield, Indiana, to provide its TubeRack systems to a brand-new distribution facility for United Natural Foods, Inc. (UNFI) in Gilroy, Calif. UNFI is the leading independent, national distributor of natural, organic and specialty foods in the United States. The new facility, which is a 400,000 square foot building, provides jobs to more than 500 employees.

Completed in about four months, Hannibal worked closely with Storage Solutions to ensure the storage system not only met the demanding business needs of UNFI, but met seismic requirements as well as building codes and fire department compliance to ensure the new facility will be ready for distribution when its doors open in February. Given the good working relationship between the companies and a commitment to get the project done with excellence, the installation was completed by Storage Solutions' company-employed installers.

"Hannibal Industries has worked hard with Storage Solutions to come up with a system for UNFI that will meet its needs, as well as carefully planned expansion options as the company grows and evolves," said Steve Rogers, executive vice president at Hannibal. "This type of diverse warehousing setup is exactly what TubeRack is known for, as it is highly scalable and meets the ever changing business landscape. We look forward to working more with Storage Solutions and UNFI in the future."

"As a national provider, Storage Solutions' primary goal is to give our customers a partner they can count on to get their projects done right, no matter the size of the facility or where it is located across the U.S.," Kevin Rowles, president of Storage Solutions. "We have been working with Hannibal Industries on the UNFI project and together we have built a system that will help UNFI distribute and deliver its products to its customers in a more efficient manner. We are pleased with our work with Hannibal and have plans to create solutions for customers in the future."

Hannibal Industries is a pallet rack manufacturer providing material handling solutions to the food and beverage, home improvement, warehouse distribution, manufacturing, cold storage distribution, retail, archive storage, automotive and Third-Party Logistics Providers (3PL). The company works closely with system integrators, consultants and its distributors to offer innovative solutions.

Additional information on Hannibal Industries is available at http://www.hannibalrack.com, on Twitter @HannibalRack, on the Hannibal Rack YouTube channel and on LinkedIn.

About Hannibal Industries, Inc.

Hannibal Industries, Inc., headquartered in the Los Angeles metro area, is a pallet rack and steel tube manufacturer with a diverse product line that enables the company to provide material handling products to some of the largest operations in the world. This employee-owned company is the largest U.S. manufacturer of steel pallet rack west of the Mississippi River.

The company's industry leading product offering includes TubeRack, Metalsistem, Structural Pallet Rack, Roll-Formed Selective Pallet Rack, Hybrid Systems, Cantilever Systems, Pushback Systems, Pallet Flow Systems, Case Flow Systems and Drive-In Systems. Engineering and design services offered by the company include: system design; seismic engineering; permit administration; in-house installation and custom fabrication. A true innovator, Hannibal Industries was awarded patents for its pallet rack system adjustable safety restraint and TubeRack. For additional information, visit www.hannibalrack.com.

For more information, contact:

Hannibal Industries Media Relations/

Master Plan Communications, Inc.

Ashton Maxfield

949.289.6493

ashton@masterplanpr.com

or

Deborah Cser

714.310.9651

deborah@masterplanpr.com

More Info: http://www.hannibalrack.com

Copyright ©2024. All Rights ReservedDesign, CMS, Hosting & Web Development :: ePublishing