UAW strike could tangle supply chains across North America

Union walkouts hit just three auto plants on Friday, but movement is first to strike GM, Ford, and Stellantis at once

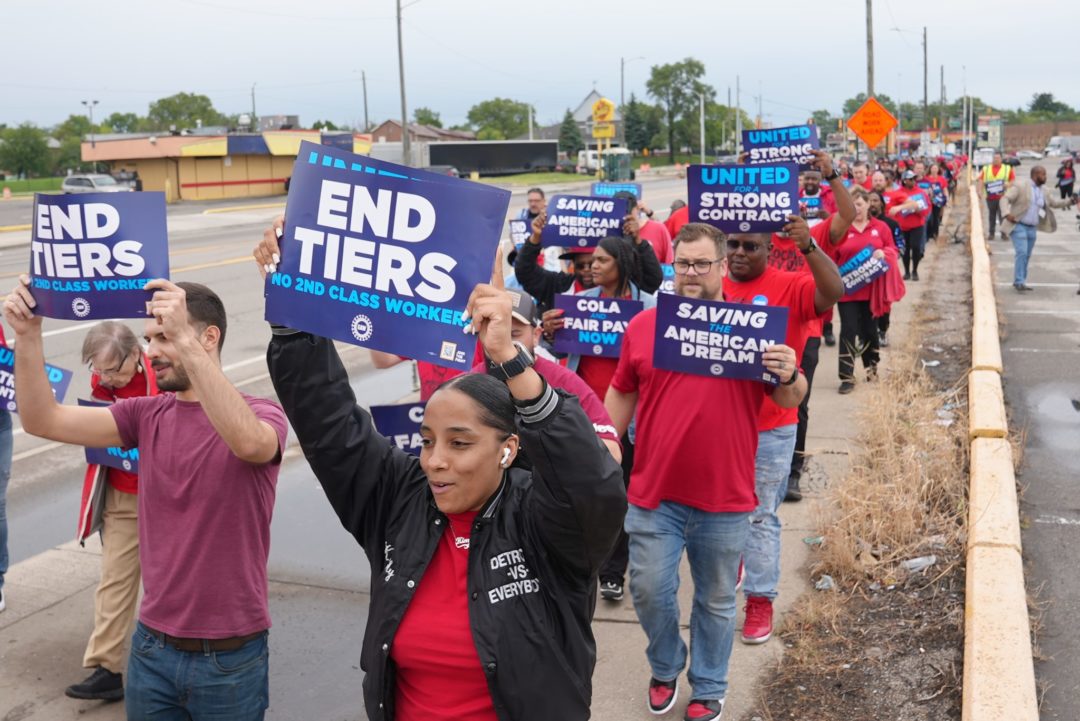

The United Auto Workers of America (UAW) strike that began today against General Motors, Ford, and Stellantis in search of higher wages and better medical benefits could soon have ripple effect impacts on manufacturers in every industry, experts say.

UAW said its members on Friday began a walkout at three sites: a GM plant in Wentzville, Missouri, a Stellantis plant in Toledo, Ohio, and a Ford plant in Wayne, Michigan. That handful of facilities represents just a small fraction of each automaker’s manufacturing might, but is significant because it’s the first time the union has struck all three companies at once.

The stakes are high on many levels—personal paychecks, corporate revenues, and far-flung supply chains—according to a blog post by Harrison Wells, vice president at LeanDNA, an inventory optimization platform provider. For example, a 40-day strike in 2019 against a single automaker led to a production loss of 300,000 vehicles and cost the automaker $3.6 billion in earnings, he said.

Set in 2023, those costs are even more clear in a post-pandemic world, where most manufacturers have been made painfully aware over the past three years of raw material, product, and part shortages triggered by transportation challenges and large scale disruptions, Wells said in a post titled "The New Disruption Economy: Why All Manufacturers Should Pay Attention to the UAW Strike."

In fact, by the end of the day on Friday, the strike had already impacted the North American automotive supply chain, showing a substantial uptick in rescheduled over the road (OTR) auto shipments originating in Mexico and bound for the U.S., and shifts in on-time deliveries. According to supply chain visibility provider FourKites, a work stoppage could reignite supply chain issues across all tiers of part suppliers and logistics service providers (LSPs).

“Companies might rush to modify purchase orders, causing a ripple effect across the entire network, including a reduced need for transportation. This could lengthen the recovery period for some LSPs who are beginning to dig out of the freight recession and cause prolonged bloat in available capacity,” Tom Gregorchik, vice president, industry strategy, FourKites, said in an email. “The UAW and the OEMs still seem pretty far apart from a deal, so I predict that volumes from Mexico will continue to fall until the two parties get closer and there’s more certainty that components from Mexico will be needed to get production going again,” Gregorchik said.

If the strike expands to additional auto plants, additional supply chain impacts could include a rise in “grey market” trade in fake parts, according to Roei Ganzarski, CEO of Alitheon, which provides technology for counterfeit identification and traceability. “A massive walkout will have ripple effects on a global scale,” Ganzarski said in an email. “A halt in production will have direct economic impacts for the workers, the Big 3 and the local economies these car businesses drive, but the hidden risks – like counterfeit parts that will undoubtedly flood the auto parts market – come at even greater costs. Shortages make people source parts wherever they can buy them, but inauthentic parts risk human safety. Car owners should be on high alert.”

As supply chain and transportation networks feel the heat from continued negotiations, industry groups are already looking to the government for help. In an effort to draw federal forces into the fray, trucking industry trade group the American Trucking Associations (ATA) criticized the White House for backing union strikers. "Does anyone think demanding a 40% pay raise is reasonable, let alone realistic? Nor is a four-day work week, paid at 40 hours. How exactly do you assemble vehicles without your employees present?” ATA President and CEO Chris Spear said in a release. “The UAW needs to stop showboating off the heels of this administration's union-biased agenda, come to the table, and put our nation's economy first."

However, powerful forces are also backing the UAW strikers, as Teamsters General President Sean M. O'Brien called on Ford, Stellantis, and GM to provide “respect at work and dignity in retirement” to UAW members. "The International Brotherhood of Teamsters, including our members in the carhaul industry, stand in solidarity with the United Auto Workers to get the best contract possible from America's biggest automakers. Just as the Teamsters saw at UPS, record profits at any company must result in record contracts for the workers who make those profits possible,” O'Brien said in a release. "You can be sure there is no division in America's labor movement today. And you are urged to remember that Teamsters don't cross picket lines."

Related Articles

Copyright ©2024. All Rights ReservedDesign, CMS, Hosting & Web Development :: ePublishing