Upload your press release

Caster Concepts Unleashes the Power of TWERGO MAXX

Albion, MI - Widely known as the maker of casters, wheels and tread with plenty of muscle, Caster Concepts Inc., unveiled its newest pumped-up industrialized caster: TWERGO® MAXX.

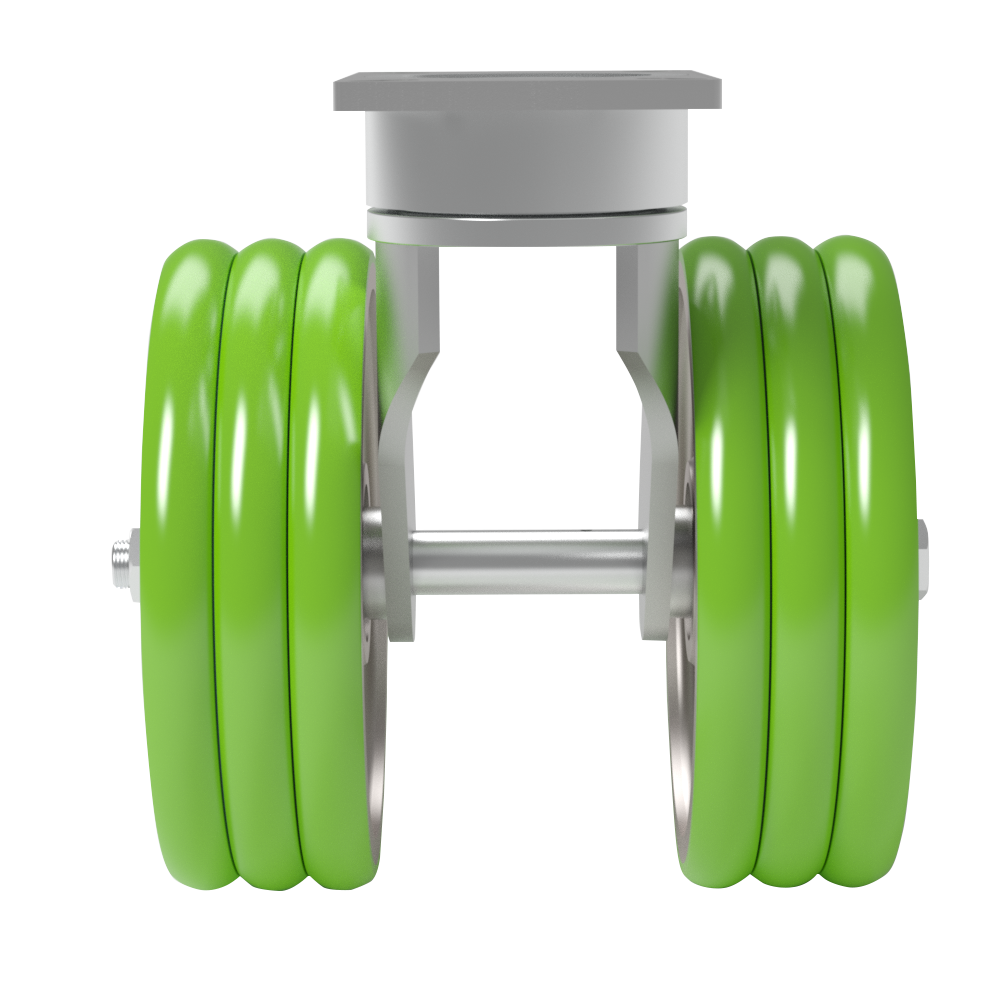

Aimed at delivering the strength of titans, TWERGO MAXX is designed to move up to 4,200 pounds without the user breaking a sweat or throwing out a back. The new member of the TWERGO line of heavy-duty casters looks like a barbell, with wheels on either side of the rig. Its unique configuration enables the casters to rotate independently, minimizing rolling resistance.

For employees tasked with moving large loads of materials, TWERGO MAXX alleviates the risk of injury by reducing the amount of force needed to push and pull. Injuries associated with overexertion, such as pushing and pulling heavy materials, are the most common workplace injury in the U.S., costing employers nearly $13 million, according to the 2019 Liberty Mutual Workplace Safety Index.

"Our engineers have refined the force-reducing technology used to design our products and created TWERGO MAXX, which enables operators to move extremely heavy loads, reducing their threat of injury and improving their productivity," said Bill Dobbins, M.D., president and CEO of Caster Concepts and a retired physician who treated manufacturing-workplace injuries.

A recent application of TWERGO MAXX at an automotive plant helped operators move 3,500 pounds, reducing the average push/pull force of 90 pounds to 50 pounds.

TWERGO MAXX wheels aren't just for carts. They're ideal for AGV's and Tuggers, where high weight capacities are a must. They're also reliable at higher speeds and are available in two- and three-wheel configurations.

TWERGO MAXX benefits at a glance:

• Parabolic Wheel Face: Achieves an average of 25 percent reduction in initial push force to start rolling;

• Precision Sealed Ball Bearing: Sealed bearings are maintenance-free to eliminate costs and extend life;

• Aluminum Wheel Core: Rust-proof core is lightweight yet durable;

• Independently Rotating Wheels: Reduces friction and force exerted;

• Thick Tapered Tread: Reduces friction and results in longer use.

For more information on TWERGO MAXX wheels, you can download the product sheet here or call a Caster Concepts representative at 517-680-7950 or email customercentral@casterconcepts.com.

About Caster Concepts

Caster Concepts designs and builds industrial casters and wheels for virtually any application. ISO 9001-2008-certified, Caster Concepts manufactures heavy-duty products to withstand impact, corrosion, temperature extremes and industrial chemical environments. Caster Concepts' multifunctional casters and wheels provide solutions in industrial, automotive, food service, aerospace, material handling and many other demanding markets. Visit CasterConcepts.com.

Company: Caster Concepts Inc.

Company URL: https://www.casterconcepts.com/caster-wheels/twergomaxx-casters/

Related Articles

Copyright ©2024. All Rights ReservedDesign, CMS, Hosting & Web Development :: ePublishing