Oracle releases artificial intelligence (AI) applications for manufacturing

Business software giant Oracle Corp. said Monday it has launched a set of cloud-based artificial intelligence (AI) applications that can improve efficiency in manufacturing and supply chain operations by identifying patterns and making predictions based on vast amounts of data.

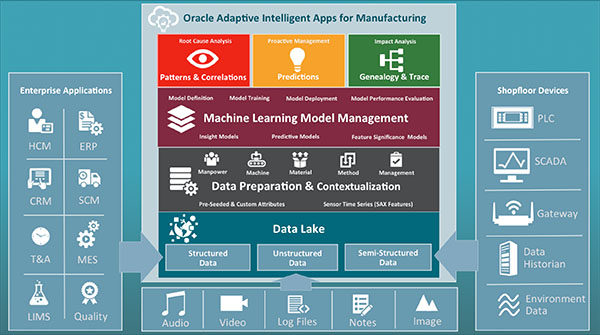

Known as the "Adaptive Intelligent Applications for Manufacturing," the software uses machine-learning algorithms to analyze the data generated in production environments. The algorithms can spot production anomalies, identify their root cause, and predict events before they occur, the Redwood Shores, Calif., company said.

Organizations can apply those results to reduce costs and increase yields by foreseeing faulty processes and tracking their impact at any point from inventory production through to customer delivery, Oracle said.

The product is Oracle's latest move to expand its offerings in the logistics software space, following the company's 2016 purchase of warehouse management system (WMS) vendor LogFire Inc. Since then, Oracle has made upgrades to that WMS product, released new versions of its cloud-based supply chain management product, and launched a suite of supply chain automation applications.

The new AI software links together data from information technology (IT) sources—such as enterprise resource planning (ERP) and customer relationship management (CRM) platforms—with data from the operational technology (OT) realm, such as internet of things (IoT) information about machines and equipment, or external environmental data such as humidity and temperature.

By examining those diverse inputs, the AI software can identify patterns and correlations in business metrics, trace the "geneology" of production processes, and perform predictive analytics to predict the likelihood of certain outcomes.

"We apply algorithms to generate insights and predictions with an adequate lead time to solve or avoid the problem," Ramchand Raman, vice president of product development for Oracle AI & IoT Applications, said in an interview. "If those results come too late, you can't react, and if they are too early, they may not be accurate."

Oracle designed the platform with a simple presentation layer that makes complex data mining and machine learning outputs easy to consume, Raman said. "Historically, most of this analysis has been done by data scientists in a bunker, far from the factory floor. But we asked how the average business user can consume this, whether they are working on purchasing, logistics, maintenance, quality, or whatever," he said.

The Adaptive Intelligent Applications for Manufacturing product is intended for users in discrete manufacturing sectors like semiconductors, aerospace, and automotive, as well process manufacturing sectors like pharmaceuticals, chemicals, metals, and food and beverage.AI can help businesses make faster decisions by identifying the key factors affecting inventory quality and production, Raman said. "A product could be affected by a thousand factors, but users need to know which are the top three or top five," he said.

Related Articles

Copyright ©2024. All Rights ReservedDesign, CMS, Hosting & Web Development :: ePublishing