Making light work of labeling

For Cincinnati-based energy-efficient lighting specialist LSI Industries Inc., the LED (light-emitting diode) revolution has brought both challenges and opportunities. On the plus side, it's been good for LSI's LED-based fixtures business, kicking demand into high gear. On the downside, it has introduced some complications to the back end of the operation.

One area that was feeling the strain was product labeling. As LSI's lighting division continued to expand its product offerings and customer base, the company found it increasingly challenging to manage the vast and growing number of safety labels required for its electrical products. Essentially, the division needed a way to make the process more efficient. So a couple years back, it launched a search for a solution that would streamline the task.

A screen shot from the Codesoft bar-code label design system that LSI is using. The software integrates with ERP software, allowing LSI to eliminate static label files and their associated maintenance.

A screen shot from the Codesoft bar-code label design system that LSI is using. The software integrates with ERP software, allowing LSI to eliminate static label files and their associated maintenance.

As for what it wanted in a new system, LSI had a pretty clear idea of its requirements. For instance, it wanted the capacity to print labels from multiple locations as well as to proactively manage—and comply with—ongoing and emerging product safety requirements. But most of all, LSI was seeking a way to simplify the labor-intensive process of maintaining and updating its label files.

"Over the years, we had developed thousands of labels that required a serious commitment in time and effort to maintain," said Tom Cantrell, LSI's manager of product and manufacturing support, in prepared remarks. "We were looking to reduce the time spent maintaining these files."

LSI found the solution it sought in two software packages from Teklynx International, a Whitefish Bay, Wis.-based bar-code and radio-frequency identification (RFID) labeling software developer. The first, Codesoft, is a bar-code label design system that can be integrated with the customer's enterprise resource planning (ERP) software. Linking its label design software with its ERP would allow LSI to eliminate static label files—along with the associated ongoing maintenance of those files—and replace them with database-driven templates.

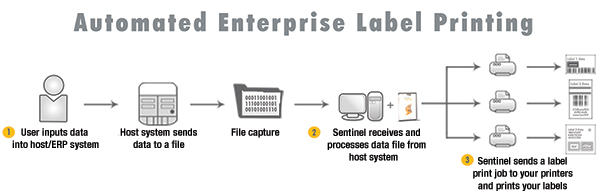

The second, Sentinel, is a label printing automation solution that enables users to centrally print on hundreds of printers at the same time. With the new software, LSI would be able to print labels at multiple facilities, with plenty of capacity to accommodate future growth.

The Sentinel label printing software lets LSI print labels from hundreds of printers at the same time. LSI would be able to print labels at multiple facilities if desired.

The Sentinel label printing software lets LSI print labels from hundreds of printers at the same time. LSI would be able to print labels at multiple facilities if desired.

Using the new software packages, LSI says it has:

- Eliminated 6,000 static label files by replacing them with the database-driven templates, reducing ongoing label file maintenance by 80 percent and cutting processing time to minutes from days;

- Acquired the capability to print to a virtually unlimited number of printers, supporting its multi-user, multifacility environment; and

- Gained access to over 100 bar-code symbologies, improving its ability to comply with product safety requirements.

For his part, Cantrell says the new solution has made label management far more efficient. "Say I need to change the word 'luminaire' to 'fixture,'" he said. "Now I can change it in one place instead of going through all those files. And we can incorporate any of the outlying facilities in addition to the corporate office, so it gives me a wealth of opportunity to standardize processes and share our knowledge base."

Related Articles

Copyright ©2024. All Rights ReservedDesign, CMS, Hosting & Web Development :: ePublishing