Which dimensioning system is right for you?

If it seems you're hearing a lot about warehouse dimensioning systems these days, there's a reason for that. Now more than ever, warehouses and DCs need to have accurate measurements for all of their products and shipments. For parcel shipments, that dimensional data is crucial for accurately calculating shipping costs and choosing the right carton. For pallet shipments, dimensional data can help users calculate exactly how much room a load will occupy in the trailer. And inside the DC, accurate dimensional data makes it easier to slot items and optimize the facility's storage space.

While you could send an employee out with a tape measure to record the height, width, and length of each product or carton, that approach is time-consuming and error-prone. One small improvement is using an electronic tape measure (e-tape) or digital tape measure that will take and record the measurements for you. But the more products your distribution center deals with, the more sense it makes to use automated dimensioning equipment that requires minimal human involvement.

Before you begin looking at dimensioning equipment, however, it helps to know what your options are and which types of units work best for what applications. In general, dimensioning systems fall into two major categories: systems that are designed to measure pallet loads, and systems designed to measure parcels or individual items. That second category—parcel dimensioners—can be further broken down into two types of units: static tabletop dimensioning systems and in-motion systems that measure items as they pass through a tunnel. What follows is a look at these systems as well as some of their strengths and weaknesses.

DIMENSIONING FOR THE WHOLE PALLETAs its name suggests, a pallet dimensioning system is used to calculate the exact volume of a pallet load before it's placed in a trailer. Typically, these systems are mounted on the ceiling or on a column, says Jason Wiley, business manager of Mettler Toledo, which makes dimensioning equipment. Under this method, the pallet to be measured is transported via forklift to the system, where it is scanned and dimensioned.

Pallet dimensioners are a good fit for trucking companies looking to calculate shipping charges based on the exact volume a load takes up in the truck, not the overall dimensions of a standard pallet, says Justin Headley, marketing manager for the dimensioning system manufacturer CubiScan. They also provide a way for shippers to avoid freight-charge surprises at the end of the month and to collect data that can be valuable in resolving disputes with carriers, he says.

Headley warns, however, that not all pallet dimensioners are created equal. "Do your homework before choosing a vendor," he says. "Make sure they have the technology to 'see' all five sides of the load, can properly scan the entire load for bulges or bumps, and have a software interface that integrates with your shipping software."

For all their strengths, pallet dimensioners also have their weaknesses. Perhaps the biggest downside to using these devices is that the process of picking up, moving, and scanning pallets is a bit cumbersome, says Jack Ampuja, president of Supply Chain Optimizers, a consulting firm that's been involved in numerous packaging optimization projects. "I don't know how many minutes the process takes, but it certainly isn't a five-second deal," he says.

The good news, Ampuja says, is that "in-line" pallet dimensioning systems are on the horizon. He reports that manufacturers are currently testing a couple of different solutions, including one in which laser sensors are placed on the forklift itself to measure the load as it's picked up, and one that captures the load's measurements as a truck drives through a tunnel outfitted with sensors.

DIMENSIONING FOR PARCELS

In contrast to pallet dimensioning systems, parcel dimensioning systems are already available in both static and in-line varieties. The first type, the static dimensioning system, could be considered a "semi-automated" solution. To use this type of machine, an operator places a parcel or item on the dimensioning system, which then measures (and often weighs) the product. The equipment can be stationary—for example, located at a packing station—or placed on a cart and wheeled around the distribution center.

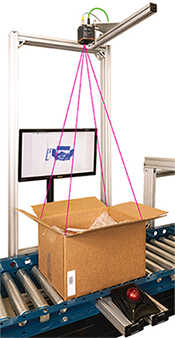

With an in-line/in-motion or dynamic dimensioning system, by contrast, a package or parcel moves down a belt and passes through a tunnel, where its dimensions are captured by either a 3-D camera or laser sensors. These tunnels are usually placed after pick and pack stations and before labeling and shipping stations, says Dan Hanrahan, president of warehouse automation specialist Numina Group.

Both static and in-line dimensioners can be used in DCs at the outbound end to gather dimensional data needed for calculating shipping costs. They can also be used at a facility's inbound end to gather the dimensions of stock-keeping units (SKUs) in order to calculate how much storage space the item will require or determine what size carton to use for shipping.

THE SCOOP ON STATICStatic dimensioners come in an almost dizzying array of varieties, with different brands providing varying levels of accuracy and requiring varying amounts of labor. With respect to accuracy, for example, some dimensioners can provide a very precise 3-D image of an irregular-shaped item, while others provide more rectilinear dimensions, says Will Crosby, director of marketing for the dimensioning system provider QubeVu. Wiley of Mettler Toledo further advises potential buyers to make sure that any machine they're considering is NTEP (National Type Evaluation Program) certified by the National Conference on Weights and Measures.

Different static dimensioners use different types of sensing technology to take measurements, including laser triangulation, which measures the reflection or displacement of a laser beam; sonic transducer technology, which does the same with sound waves; and optical imaging technology, which often uses 3-D cameras. Some systems may use a combination of these methods because different technologies provide more accurate measurements for different types of items. (For example, lasers might be better at measuring shiny objects than cameras are.) Users should also be aware that a dimensioner's accuracy depends not only on the quality of the equipment—the actual laser or camera—but also on the software that analyzes the information received from the camera or laser, Crosby says.

Different static dimensioners also require different amounts of labor, according to Crosby. Some require the operator to line up the box or item precisely with the dimensioner's edge and press a button or pass a metal bar over it to get the measurements. These types typically use laser-based technology, he says. Other dimensioners simply require the operator to place the item on or under the dimensioner, which then automatically detects the item and dimensions it in tenths of a second.

MEASURING ON THE MOVECompared with static dimensioners, in-motion parcel dimensioners are typically faster and better suited for high-throughput operations. As for how manufacturers define "high-throughput" operations, that can vary. But Hanrahan says that in-line systems are good for operations that ship out 700 cartons or more a day.

In many cases, these tunnels serve not just as dimensioners but also as in-line inspection points that capture the carton's weight, bar code, and other text-based information. Some even take pictures of the parcel to provide a record of its condition at that point in the handling process. Units with these capabilities can be used for pick validation or defect detection before an outbound item or parcel is placed in a truck, Hanrahan says.

In-line systems are typically more expensive than static solutions, but prices have been dropping as camera technology advances, Hanrahan says. He reports that dimensioning software can currently be added to a scanning tunnel for under $5,000.

The one drawback of in-line tunnels is that they don't always work with every shape, says Kim Karvonen, senior sales and business development executive for QubeVu. For this reason, Hanrahan recommends that companies use static dimensioners if they're trying to obtain cube dimensions for slotting, storage, or cartonization purposes.

THE FINAL TESTOnce you've decided what general type of system is right for your operation, it's time to begin evaluating different manufacturers' products. To ensure a fair comparison, Wiley recommends conducting a "bake off" where the systems are compared side by side using the same types of parcels or loads you handle in your daily operations. "Don't take the manufacturers' word for it," he says. "Measure and test for yourself, so that you get the right technology and solution for you."

What's the best dimensioning system for you? The answer will depend on your slotting and shipping volume, the size and types of items you handle, and how much you want to spend. Here are some questions to ask yourself as you narrow down your search:

1. What are you dimensioning? This is more than just a matter of knowing whether you'll be measuring parcels, pallets, or letter packs, says Jason Wiley of Mettler Toledo; you also have to consider factors like the items' shape (that is, whether they're regular- or irregular-shaped). Don't immediately assume that all your items are regular-shaped, adds Will Crosby of QubeVu. For example, polybagged items might seem regular-shaped but a package may bulge depending on what's in it or how it's packed—which could prevent some machines from obtaining accurate measurements.

2. What are the maximum/minimum lengths, widths, and heights

3. What is your throughput? Often, this will determine the degree of automation you need.

4. What is the surface of the item that you're dimensioning? Is it shiny? Is it dark? Some systems will have a harder time measuring those items than others, Wiley says. For example, a dimensioner that uses lasers may be better at measuring items with reflective surfaces than one that uses a camera.

5. How much are you willing to invest? When determining how much you can spend on dimensioning equipment, be sure to take into consideration any labor savings that the equipment might provide.

6. How well will the dimensioning system interface with your shipping software—such as UPS WorldShip or FedEx Ship Manager—or your warehouse management system?

7. How fast do items need to be dimensioned? Crosby notes that when comparing the speeds of various models, it's important to consider not just the speed of the equipment itself but also how long it takes the operator to place the object on the dimensioner and complete any steps—like moving arms or pressing buttons—necessary for taking the dimensions.

8. Do you want to capture other information along with the dimensions? In addition to taking an object's measurements, some tabletop and tunnel systems can also determine the item's weight, scan bar codes and text, and even capture an image of the item itself.

Related Articles

Copyright ©2024. All Rights ReservedDesign, CMS, Hosting & Web Development :: ePublishing