Sick AG sees "indoor localization" as key to DC efficiency

German sensor manufacturer Sick AG makes camera tunnels that can read barcodes on parcels riding the high-speed conveyors used in many UPS Inc. and FedEx Corp. facilities, but the company sees a future with much wider tracking applications that will enable the tracing of assets throughout the DC, Sick said today.

By using an array of sensors attached to mobile assets in and around the warehouse, Sick could provide "indoor localization" services that enable users to track pallets, lift trucks, yard trucks, and other moving assets, the company said during a press tour of its offices in Waldkirch, Germany.

Sick would accomplish that by using laser-based LIDAR range-finding scanners and ultra-wideband (UWB) data communication technology to generate geopositioning data on objects that move far beyond the controlled environment of the conveyor belt, said Bernd von Rosenberger, Sick's vice president of Global Industry Center Logistics Automation.

Collecting that information could provide benefits far beyond just locating those items, enabling businesses to analyze the valuable data and improve the flow of goods throughout the building, Rosenberger said. "The objective is to get more efficiency, not just to get more transparency," by identifying places where vehicles have a long docking time at a certain station or finding ways to reduce their retention time, he said.

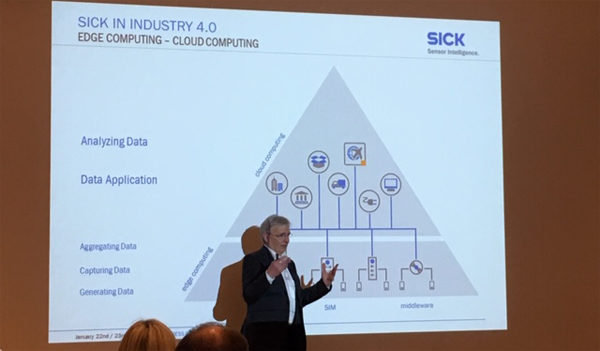

Sick sees indoor localization as one step in its plan to enable a suite of Industry 4.0 services, a term which describes production and logistics operating with single, personalized items instead of bulk handling and mass manufacturing.

The trend can be seen in the progression from single unit production to assembly line flow and finally to flexible production of single items, Bernhard Muller, Sick's senior vice president for Industry 4.0, said today. "The goal is to have a lot size of one, at the speed and cost of mass production," he said.

Sick plans to launch the new product family at the LogiMAT 2019 show in Stuttgart and the ProMat show in Chicago this spring.

Related Articles

Copyright ©2024. All Rights ReservedDesign, CMS, Hosting & Web Development :: ePublishing